Contact Us

Technology

Nozzle-less Difference USI’s core technology is called

How it Works The Ultra-Spray head is an integrated assembly consisting of an ultrasonic transducer with a spray forming tip, a liquid applicator

The coating liquid is delivered to the spray-forming tip on the ultrasonic transducer by

Air directors are used to

Nozzle-less Ultrasonic Spray Head

This nozzle-less ultrasonic spray head produces a substantially rectangular shaped coating distribution on the substrate. The rectangular shape is ideal for producing a uniform coating on a flat surface. The actual coating distribution is uniform across about 90% of the width of the sprayed pattern and the edges are “feathered” from the applied coating thickness to zero thickness. The figure below shows the spray pattern distribution comparison between the nozzle-less spray head and a traditional spray head as well as the resultant distribution after a series of overlapping passes.

Ultra-Spray vs Spray Nozzle

Precision Metering Pump (PMP) A highly accurate liquid delivery system has been developed that incorporates a positive displacement metering pump. The liquid flow rate is controlled by

Since some coating liquids have suspended particles that can settle this liquid delivery system has the capability to keep the coating mixed while maintaining an accurate and repeatable flow rate of the coating to the spray head.

Precision Metering Pump (PMP)

A dual pump version is also available that allows continuous operation, without the need to wait for the single pump to refill. With this configuration, as one pump is being used to feed the spray head, the other pump is being filled from the holding reservoir. The dual pump can also be configured to recirculate and stir the coating liquid, thus ensuring that the suspended particles do not settle out in the liquid feed lines or holding reservoir.

Dual PMP with Stirring and Recirculation

The Coating System Platform The coating system platform consists of an X-Y-Z-Ɵ-Ø gantry system for the motion and positioning of the nozzle-less ultrasonic spray head, as well as integrated control of the precision metering pump liquid delivery system, and transport mechanism for the carriers. All critical process parameters are managed by the platform software and control system. Additionally, a log of the critical process data is recorded and stored in a process log file.

Prism Coating System Platform

Coating Thickness Uniformity In general, the uniformity and thickness of the applied coating layer are directly related to the following factors:

- Uniformity and stability of the spray pattern produced by the ultrasonic spray head

- Accuracy and stability of the coating flow rate delivered to the ultrasonic spray head

Consistency of the speed of the ultrasonic spray head relative to thesubstrate - Programmed coating recipe –

number of applied layers, the application path, and the coating flow rate

The speed and motion path of the ultrasonic spray head is controlled with a closed-loop servo drive system. The servo drive is tuned for uniform head speed so the variation of the head speed is negligible. The liquid flow rate is determined by the rate of displacement of a piston in the pump. The motion of the piston is controlled by a micro-stepping drive system so the variation of liquid flow rate is also negligible.

For a given coating recipe, the variation in the total amount of liquid applied to the substrate is less than ±0.1%. This can easily be verified since the system software logs the total amount of liquid applied to each substrate that is coated. Any variations in the head speed and the liquid flow rate are accounted for in the process log

Examples of the coating uniformity achieved with

Example #1 – Photoresist on Touch Panel Glass

Touch Panel Display

Measured Thickness Across Surface of Touch Panel Glass Plate

In this example, a 10% solids formulation of photoresist is applied to the touch panel glass plate at a wet film thickness of 15 microns. The glass plate is dried on a hotplate and the resulting dry thickness is

Example #2 – Fuel Cell Coating

Precious Metal-Based Catalysts

Catalyst on Nafion Membrane

In this example, a precious metal-based catalyst is formulated at 5% solids by weight. The required loading is 1.5 mg per square

Example #3 – EMI Shield Coating to Components

EMI Shield Coating on Component

EMI Shield Coating

In this example, a

Example #4 – Anti-reflection Coating to Solar Glass

Solar Glass Panel

In this example, an anti-reflection coating is applied to a 1,200 mm x 600 mm glass plate. To provide the required anti-reflection properties a uniform coating layer thickness of 120

Target: 120 nm; Ave.: 120.2; Min.: 117.5 ; Max.: 122.9; S.D.: 2.1

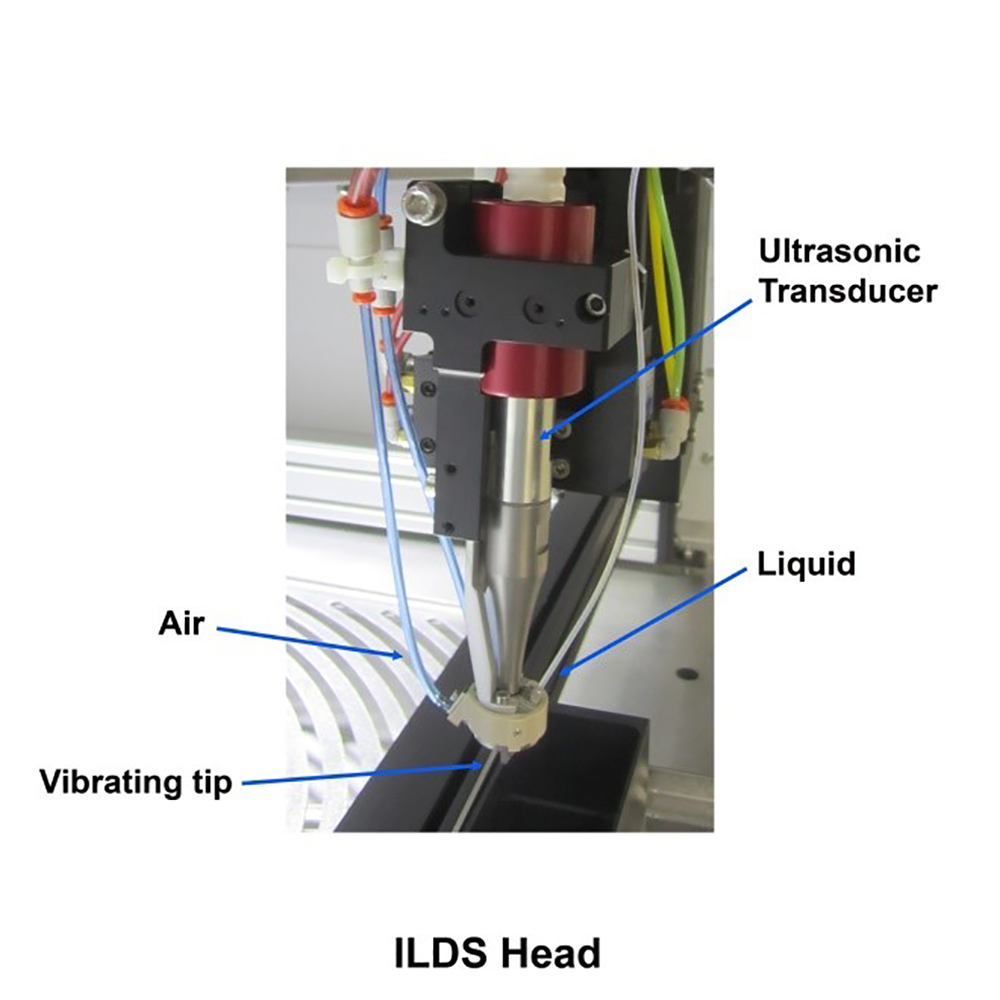

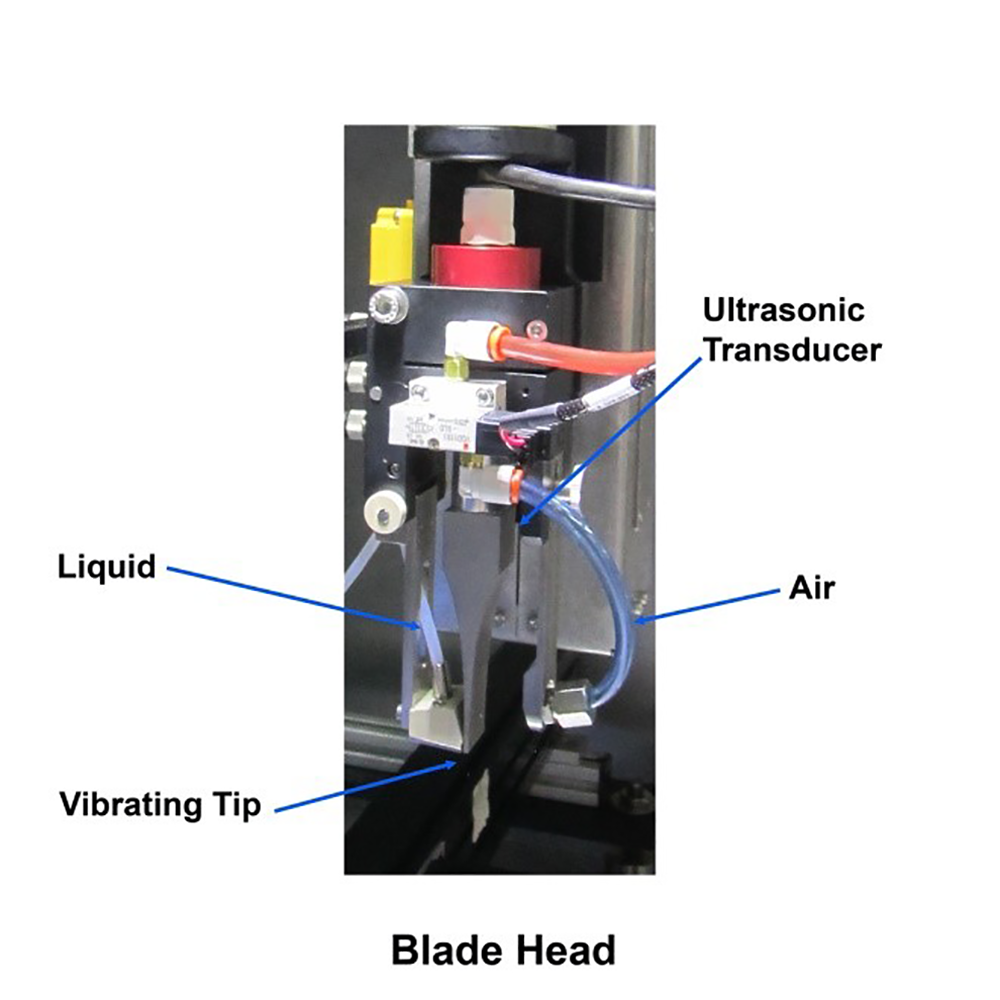

Ultrasonic Spray Heads – CAT ILDS Head and Blade Head Two basic ultrasonic spray head types are available: the Dual Mode CAT ILDS Head and the Blade Head.

ILDS Head

The ILDS Head has two (2) modes of operation; wide mode and narrow mode. Each mode of operation is selected in the Prism platform software via the coating recipe and can be selected at any time without any mechanical adjustment or other intervention. The spray is expanded to a rectilinear pattern in the wide mode and focused in a narrow circular pattern in the narrow mode. The particular mode of operation is selected based upon the particular coating application requirements. The width of the spray pattern produced by the ILDS head is from approximately 2 mm to 30 mm and this head is typically used to coat smaller areas.

ILDS Ultrasonic Spray Head

Blade Head

The blade head is designed to produce a wide rectilinear pattern from about 25 mm to 300 mm wide. This head is typically used to coat larger areas quickly. A variety of blade head models are available to meet specific coating application requirements.

Ultrasonic Blade Head

Since the spray is produced with ultrasonic energy rather than pressure, and because a low-velocity air stream is used only to shape the spray,

All process parameters for the Ultra-Spray head are set electronically for maximum control and flexibility, including:

- Liquid flow rate

- Air pressure

- Head height

- Head speed

- Motion path

Liquids Applied with Ultra-Spray Technology A wide variety of coating liquids can be applied with Ultra-Spray ultrasonic spray head technology from solutions and mixtures to high solids slurries and suspensions. A partial listing of these liquids include:

Solutions & Mixtures

- solvents

- aqueous based coatings

- polymers

- urethanes

- acrylics

- photoresists

- polyimides

- anti-reflective coatings

- anti-smudge coatings

- anti-scratch coatings

- optical coatings

- etc.

Slurries & Suspensions

- precious metal / carbon based catalysts

- ceramic based catalysts

- conductive inks

- nano particle coatings

- EMI shield coatings (high solids)

- etc.

Medical & Biomedical Coatings

- drug eluting coatings

- bioresorbable polymers

- anti-restenosis coatings

- reagents

- protective coatings

- diagnostic agents

- theraputic agents

- disinfectant agents

- etc.

| Coating Head Selected & Optimized for Your Application | |||

|---|---|---|---|

| Model | Pattern Width (mm) | Liquid Types | |

| CAT 35 ILDS | 5 – 30 | Solutons & slurries | |

| CAT 60 ILDS | 2 – 15 | Low viscosity solutions | |

| CAT 35 Blade | 25 – 150 | Solutions & slurries | |

| CAT 45 Blade | 25 – 150 | Solutions & slurries | |

| Step 35 Blade | 25 – 150 | Solutions | |

| Step 45 Blade | 25 – 150 | Solutions | |

| Step 60 Blade | 25 – 150 | Low viscosity solutions | |

| Step 45 Blade – AR | 25 – 100 | Anti-reflective & optical coatings | |

| Step 45 Blade – Wide | 50 – 300 | Solutions | |

| Micro-Line | 1 – 3 | Low viscosity solutions | |

USI Download Center

To download technical articles and product brochures, please click the following link:

USI Technical Library